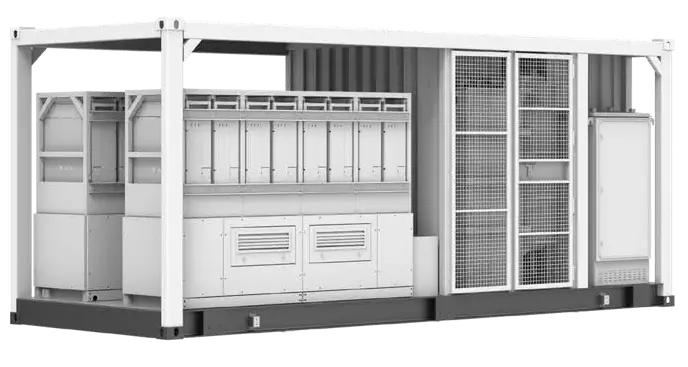

Step-up Transformer Skid Station

Brunstock’s integrated step-up transformer skid station is composed of an energy storage converter PCS, a step-up transformer, a ring main unit MV switchgear, communication power cabinet and supporting auxiliary system.

Our prefabrication strategy means that the skid station is manufactured and pre-commissioned in the factory before delivery. This saves on-site construction, installation and commissioning time. Reduced site labour costs can be substantial in the often remote project locations for battery energy storage systems.

Your Brunstock skid station can be customised in size and arrangement according to the space of the site and the location of the BESS.

Skid Station parameters

| Product Model | 3MWh BESS | 5MWh BESS central PCS | 5MWh BESS string PCS |

| DC-side parameters | |||

| Max. DC voltage | 1500V | 1500V | 1500V |

| Battery voltage | 1000V | 1000V | 1000V |

| Number of DC input paths | 2 | 4 | 24 |

| AC-side parameters | |||

| Rated power | 3450kW (1725kWx2) | 5000kW (1250kWx4) | 5000kW (215kWx24) |

| PCS nominal AC voltage | 690V, 3W+PE | 690V, 3W+PE | 690V, 3W+PE |

| PCS AC voltage range (adjustable) | 607~759V | 607~759V | 607~759V |

| Nominal grid frequency | 50Hz/60Hz | 50Hz/60Hz | 50Hz/60Hz |

| AC voltage distortion | <1.5%(100% linear load) | <1.5%(100% linear load) | <1.5%(100% linear load) |

| Power factor | -1~+1 | -1~+1 | -1~+1 |

| Harmonic (THDi) | <1.5%(100% load) | <1.5%(100% load) | <1.5%(100% load) |

| Unbalanced load capacity | 100% | 100% | 100% |

| Nominal grid frequency | 50/60Hz | 50/60Hz | 50/60Hz |

| Transformer parameters | |||

| Isolation mode | Oil-immersed transformer | Oil-immersed transformer | Oil-immersed transformer |

| Transformer rated power | 3450kVA | 5000kVA | 5000kVA |

| Rated voltage ratio | 0.69kV/35kV (10kV~35kV optional) | 0.69kV/35kV (10kV~35kV optional) | 0.69kV/35kV (10kV~35kV optional) |

| Transformer vector | Dy11y11 | Dy11y11 | Dy11y11 |

| Transformer cooling type | ONAN | ONAN | ONAN |

| Basic parameters | |||

| Dimensions (L x W X H) | 6058 x 2438 x 2896mm | 12192 x 2438 x 2896mm | 12192 x 2438 x 2896mm |

| Weight | About 15 t | About 23.5 t | About 23.5 t |

| Operating temperature range | -30-+50°C | -30-+50°C | -30-+50°C |

| Max. altitude | 5000m (>2000m degrating) | 5000m (>2000m degrating) | 5000m (>2000m degrating) |

| Protection level | IP54/IP68 | IP54/IP68 | IP54/IP68 |

| Relative humidity | 0-95% | 0-95% | 0-95% |

| Communication protocol | Modbus TCP, IEC104, IEC61850 | Modbus TCP, IEC104, IEC61850 | Modbus TCP, IEC104, IEC61850 |

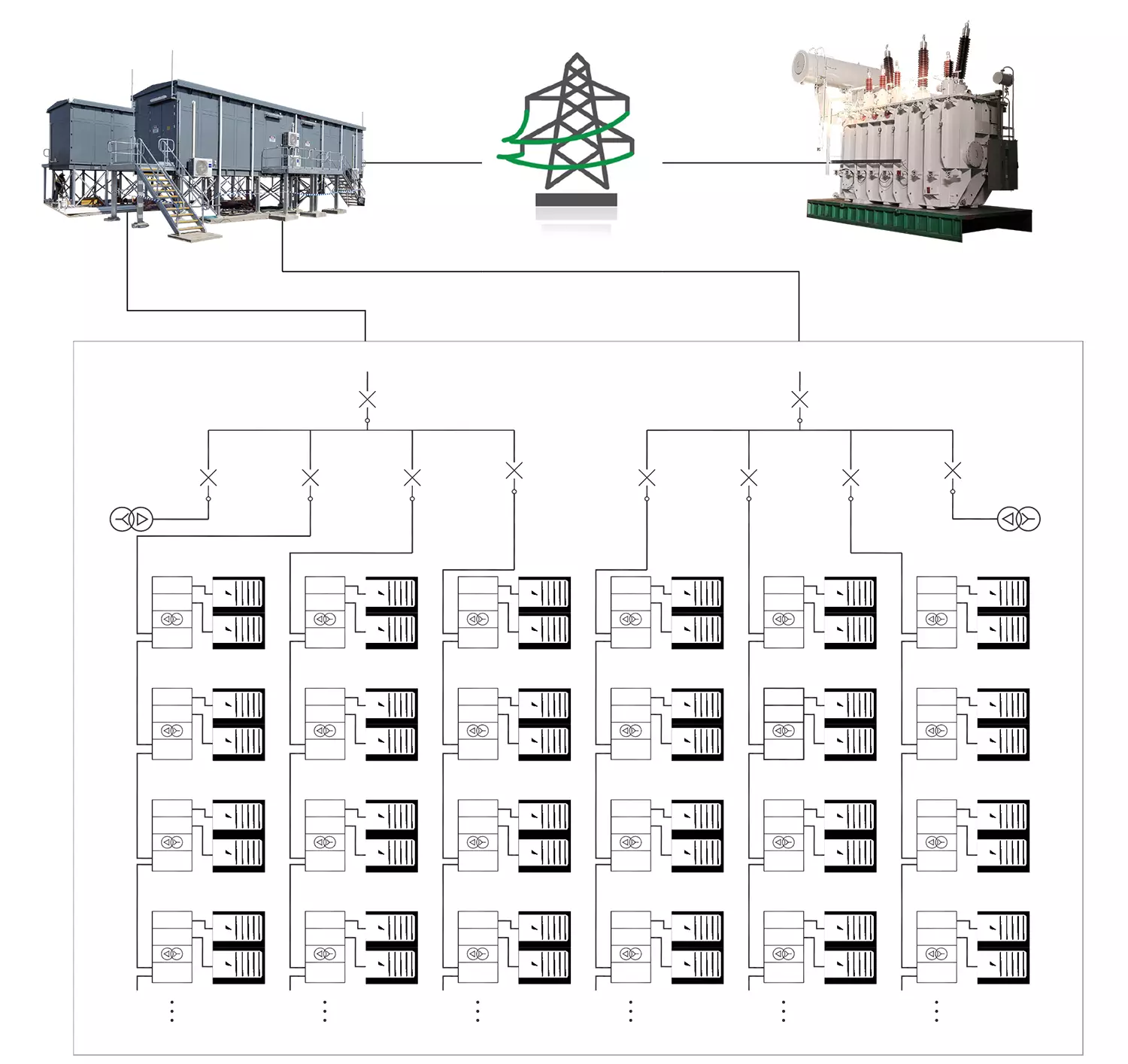

Grid connection example 1

A BESS usually connects to a high voltage grid network through the below equipment:

- Step-up skid station

- Secondary collector station

- Primary collector station

Grid connection schematic

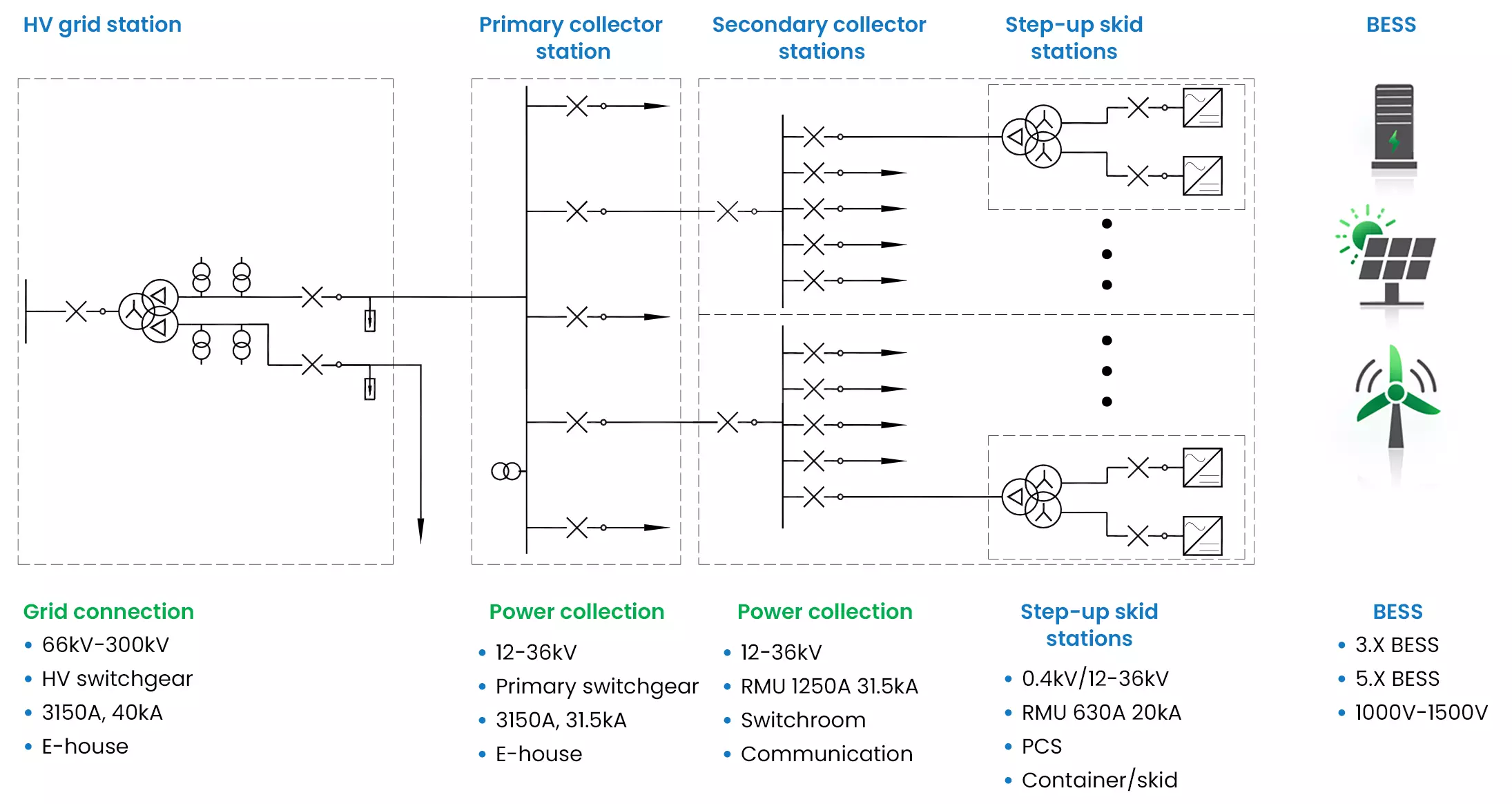

Grid connection example 2

The grid connecting system consists of step-up skid stations, secondary and primary prefabricated switch rooms and an HV prefabricated substation from 66kV to 300kV. Advantages of using Brunstock products include:

- Fast delivery

- Save space on site

- Reduce on-site construction time to maintain project schedule

- Decrease labour cost significantly thanks to much of the equipment being factory pre-assembled, pre-tested and pre-commissioned